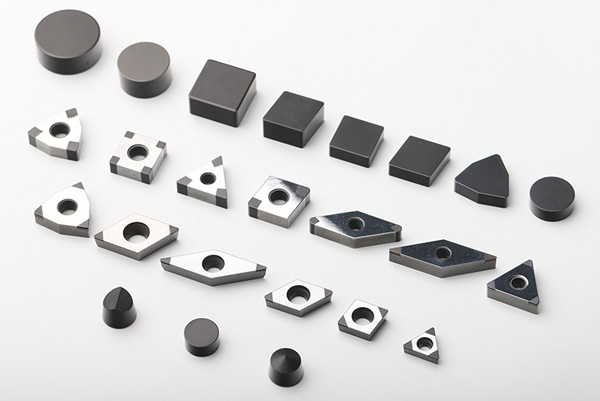

In the world of machining and manufacturing, the choice of cutting tools plays a crucial role in determining the efficiency, precision, and overall quality of the finished product. Among the various materials used for cutting inserts, Polycrystalline Diamond (PCD) and Polycrystalline Cubic Boron Nitride (PCBN) have emerged as two of the most advanced and effective options. Both materials offer unique properties that make them suitable for specific applications, enhancing productivity and performance in various industries.

What are PCD Inserts?PCD inserts are made from synthetic diamond particles that are sintered together under high pressure and temperature. This process results in a material that is incredibly hard, with a hardness rating of around 10 on the Mohs scale. PCD inserts are primarily used for machining non-ferrous materials such as aluminum, copper, and plastics. Their exceptional wear resistance and thermal conductivity make them ideal for high-speed machining applications, where traditional carbide tools may wear out quickly.

Applications of PCD Inserts:

- Aluminum Machining: PCD inserts excel in machining aluminum components, commonly used in the automotive and aerospace industries.

- Composite Materials: They are also effective for machining composite materials, which are increasingly used in various sectors due to their lightweight and high-strength properties.

- Woodworking: PCD inserts are popular in woodworking applications, providing clean cuts and extended tool life.

What are PCBN Inserts?PCBN inserts, on the other hand, are made from cubic boron nitride, the second hardest material after diamond. They are specifically designed for machining hard and tough materials, particularly ferrous metals such as hardened steel and cast iron. PCBN inserts maintain their cutting edge at high temperatures, making them suitable for high-speed machining and heavy-duty applications.

Applications of PCBN Inserts:

- Hardened Steel Machining: PCBN inserts are ideal for machining hardened steel components, which are commonly found in automotive and aerospace applications.

- Cast Iron Machining: They are also widely used for machining cast iron, providing excellent wear resistance and surface finish.

- Gear Manufacturing: PCBN inserts are frequently employed in the production of gears, where precision and durability are paramount.

Advantages of PCD and PCBN Inserts1. Extended Tool Life: Both PCD and PCBN inserts offer significantly longer tool life compared to traditional carbide inserts, reducing the frequency of tool changes and downtime in production.

2. Improved Surface Finish: The superior hardness of these materials allows for finer cutting edges, resulting in improved surface finishes on machined parts.

3. Higher Cutting Speeds: PCD and PCBN inserts can operate at higher cutting speeds, increasing productivity and efficiency in machining operations.

4. Cost-Effectiveness: While the initial investment in PCD and PCBN inserts may be higher, their longevity and performance can lead to lower overall machining costs.

PCD and PCBN inserts represent a significant advancement in cutting tool technology. Their unique properties make them suitable for a wide range of applications, from machining non-ferrous materials to handling hardened steels. By choosing the right insert for specific machining tasks, manufacturers can enhance productivity, improve product quality, and ultimately achieve greater success in their operations. As industries continue to evolve, the demand for high-performance cutting tools like PCD and PCBN inserts will undoubtedly grow, paving the way for more efficient and innovative manufacturing processes. Contact us for free quote now!