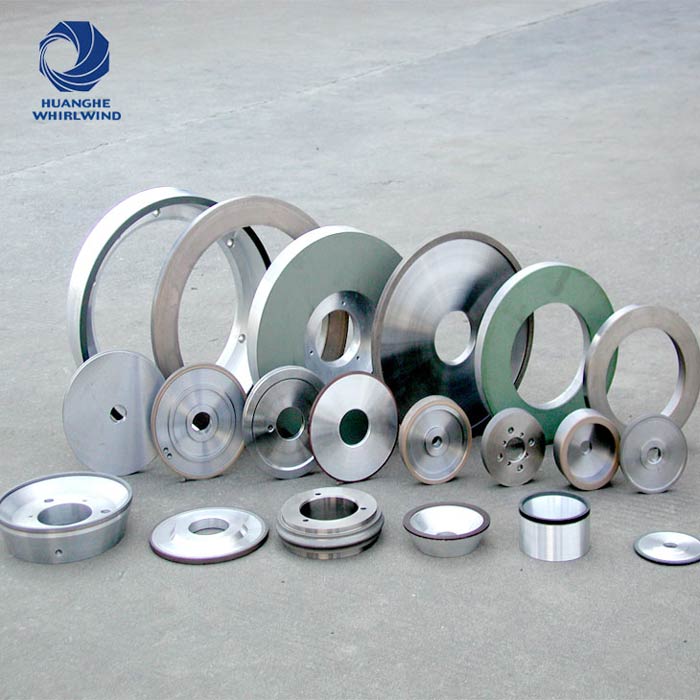

Diamond grinding wheels are one of the most advanced types of grinding wheels available in the market today. They are ideally suited for grinding hard materials such as ceramics, stone, and even metal. A diamond grinding wheel is made up of industrial diamonds that are bonded together with a metal matrix. The diamond abrasive grains evenly spread across the wheel surface working as grinding agents that remove the material during the cutting process.

These wheels have revolutionized the way we grind materials today. They have been used extensively in various applications due to their durability, precision, and cost-effectiveness. The following are some of the main applications of diamond grinding wheels.

Cutting and Grinding GlassDiamond grinding wheels are widely used in the glass industry for cutting and grinding glass. They are used to shape the glass into the desired form, and before being polished, the edges must be straightened and smoothed. Diamond grinding wheels can easily do this due to their high level of abrasiveness. These wheels can cut through glass at a much faster rate than other grinding wheels. Besides, they produce a smoother and cleaner edge, which is perfect for making intricate cuts and grinding into shapes.

Grinding and Cutting Tiles and StoneDiamond grinding wheels are also an essential tool in the construction industry. For instance, they are used for cutting and grinding tiles, stones, and concrete surfaces. This is because they are very effective in removing hard surfaces and producing smooth edges. These types of wheels have the ability to work at high speeds and generate less dust and debris compared to other wheels. Diamond grinding wheels are also capable of precision grinding, which enables them to remove just a small amount of material, giving the operator more control over shaping the material.

Sharpening ToolsAnother use of diamond grinding wheels is for sharpening tools. They can be used to sharpen a wide variety of tools, including knives, scissors, and woodworking tools. Diamond grinding wheels are much more effective and efficient at sharpening than other types of grinding wheels due to their high level of abrasiveness. They can sharpen blades by removing a very thin layer of material from the blade, which leaves the edge sharper and smoother.

Grinding MetalGrinding the toughest of metals can be a difficult task. However, diamond grinding wheels make this task effortless. They have superior grinding properties than conventional wheels, enabling them to easily remove tough material. Diamond grinding wheels are also very effective at removing burrs from metal surfaces. They are popularly used to grind aerospace alloys, hardened metals, and exotic materials.

Polishing GemstonesDiamond grinding wheels are invaluable tools in the jewelry-making industry. They can be used to polish gemstones, which is an essential step in the process of creating jewelry. These wheels make the polishing process quick, efficient, and precise. They produce a high-quality polished surface, which is perfect for showcasing the beauty and shine of gemstones.

Diamond grinding wheels are among the most advanced grinding wheels available in the market today. They are extensively used in various applications due to their durability, precision, and cost-effectiveness. These wheels are popularly used in the construction industry, glass industry, jewelry-making industry, and metalworking industry. They can grind and cut a wide variety of materials, including stone, concrete, metal, and glass. Diamond grinding wheels have revolutionized the way we grind materials today, and their usage will only continue to grow as technology advances.