In the world of precision machining, the quest for higher efficiency, accuracy, and durability is never-ending. One of the key advancements in this field is the introduction of Polycrystalline Diamond (PCD) inserts. PCD inserts have gained significant attention and popularity due to their exceptional performance and ability to revolutionize machining processes.

What is a PCD Insert?

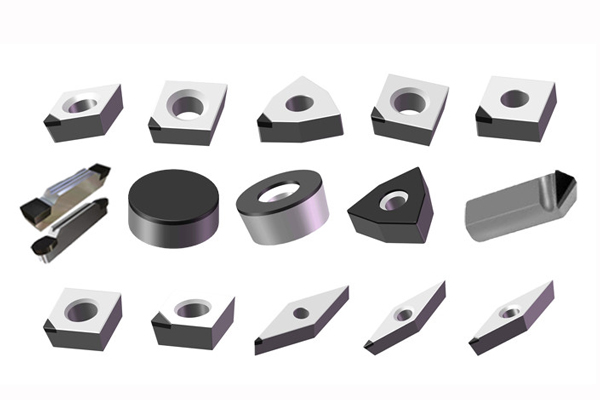

A PCD insert is a cutting tool made from a synthetic diamond material known as Polycrystalline Diamond. PCD is created by sintering diamond particles together with a metallic binder under high pressure and temperature. This process results in a super-hard material that exhibits exceptional wear resistance, high thermal conductivity, and low friction properties.

Features and Benefits:

1. Superior Hardness: PCD inserts are renowned for their exceptional hardness, surpassing that of traditional cutting tool materials such as carbide or ceramic. This hardness enables PCD inserts to withstand high cutting speeds and maintain their sharpness for extended periods, resulting in improved productivity and reduced downtime.

2. Wear Resistance: PCD inserts excel in applications where abrasive materials or high-speed machining is involved. Their wear resistance properties ensure prolonged tool life, reducing the need for frequent tool changes and increasing overall machining efficiency.

3. Heat Dissipation: PCD inserts possess excellent thermal conductivity, allowing for efficient heat dissipation during machining operations. This feature prevents overheating and extends tool life, ensuring consistent performance even under demanding conditions.

4. Surface Finish: PCD inserts deliver exceptional surface finishes due to their sharp cutting edges and minimal tool deflection. This makes them ideal for applications requiring high precision and superior surface quality, such as aerospace components or medical devices.

Applications:

PCD inserts find extensive use in various industries, including automotive, aerospace, electronics, and woodworking. Some common applications include:

1. Turning and Milling: PCD inserts are widely used for turning and milling operations on non-ferrous materials like aluminum, copper, and composites. Their ability to maintain sharpness and withstand high cutting speeds makes them ideal for these applications.

2. Hard Material Machining: PCD inserts excel in machining hard materials like hardened steels, ceramics, and advanced composites. Their superior hardness and wear resistance enable efficient machining of these challenging materials.

3. Finishing Operations: PCD inserts are highly effective in achieving superior surface finishes in applications such as fine machining of molds, dies, or precision components.

PCD inserts have revolutionized precision machining by offering exceptional hardness, wear resistance, and heat dissipation properties. Their ability to deliver superior surface finishes and extended tool life has made them an indispensable tool in various industries. As technology continues to advance, PCD inserts are expected to play an even more significant role in enhancing machining efficiency and pushing the boundaries of precision manufacturing.