Diamond grinding wheels are essential tools in various industries, particularly in metalworking, construction, and manufacturing. They are designed to grind, cut, and shape hard materials, making them invaluable for tasks that require precision and efficiency. Understanding the classifications of diamond grinding wheels can help users select the right tool for their specific applications.

1. Type of BondOne of the primary classifications of diamond grinding wheels is based on the type of bond used to hold the diamond particles. The most common types include:

- Resin Bond: These wheels are made with a resin material that provides flexibility and a good finish. They are ideal for grinding hard materials and are often used in the manufacturing of tools and dies.

- Metal Bond: Metal bond wheels are known for their durability and are typically used for heavy-duty grinding applications. They are excellent for grinding hard materials like ceramics and carbide.

- Vitrified Bond: These wheels are made from a glass-like material that offers a good balance between strength and porosity. Vitrified bond wheels are commonly used in precision grinding applications.

2. Diamond ConcentrationDiamond grinding wheels can also be classified based on the concentration of diamond particles. Higher diamond concentration means more cutting edges, which can lead to faster grinding but may also result in a rougher finish. Conversely, lower concentration wheels provide a smoother finish but may require more time to achieve the desired results.

3. Grit SizeThe grit size of a diamond grinding wheel is another critical classification. Grit size refers to the size of the diamond particles embedded in the wheel. Finer grits (higher numbers) are used for achieving a smooth finish, while coarser grits (lower numbers) are suitable for rapid material removal.

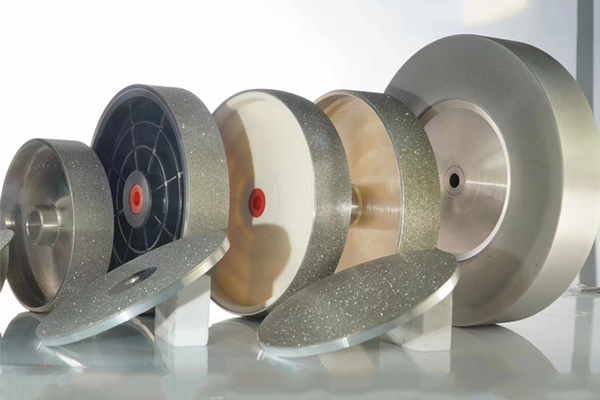

4. Shape and SizeDiamond grinding wheels come in various shapes and sizes, tailored for specific applications. Common shapes include flat, cup, and cylindrical, each designed for different grinding tasks. The size of the wheel also plays a crucial role in its performance, with larger wheels typically used for heavy-duty applications.

In summary, the classification of diamond grinding wheels is essential for selecting the right tool for your grinding needs. By understanding the types of bonds, diamond concentration, grit size, and shapes available, users can make informed decisions that enhance productivity and achieve superior results in their projects. Whether you are in manufacturing, construction, or any other industry that requires precision grinding, choosing the right diamond grinding wheel is key to success.